[Similar Product Name] Nonylphenol Polyoxyethylene Ether TX Series NP Series

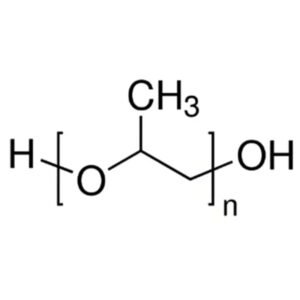

[Chemical composition] Alkylphenol Polyoxyethylene Ether

[CAS NO.] 9016-45-9

[Type] Nonionic

1. Product Property

The TX series are non-ionic surfactants produced by ethoxylation of octylphenol. They appear as clear, colorless to pale-yellow liquids (low-EO grades) or soft pastes/waxes (high-EO grades). All grades are odorless when pure, with pour points ranging from –10 °C (TX-4) to 40 °C (TX-405). They are infinitely soluble in water, ethanol, acetone, chloroform, aromatic and aliphatic hydrocarbons, and vegetable oils. Surface tension of 1 g L⁻¹ aqueous solution is ~30 mN m⁻¹ (TX-100). They exhibit excellent chemical stability over pH 2–12, low foaming tendency (TX-114), and temperature reversibility (cloud-point behavior), making them ideal emulsifiers, detergents and wetting agents.

2.TECHNICAL NORM

| Specification | Appearance(25° C) | Color Pt-Co | Cloud point°C(1% aqueous solution) | Hydroxyl value mgKOH/g | Moisture(%) | pH(1% aqueous solution) | HLB value |

| TX-4 | Colorless transparent liquid | ≤20 | – | 135~145 | ≤1.0 | 5.0~7.0 | 8~9 |

| TX-5 | Colorless transparent liquid | ≤20 | – | 122~132 | ≤1.0 | 5.0~7.0 | ~10 |

| TX-7 | Colorless transparent liquid | ≤20 | – | 100~110 | ≤1.0 | 5.0~7.0 | 10~11 |

| TX-9 | Colorless transparent liquid | ≤20 | 50~60 | – | ≤1.0 | 5.0~7.0 | 10~11 |

| TX-10 (NP-10) | Colorless transparent liquid | ≤20 | 60~67 | – | ≤1.0 | 5.0~7.0 | 12~13 |

| TX-12 | Milky white cream | ≤20 | 80~85 | – | ≤1.0 | 5.0~7.0 | ~14.2 |

| TX-13 | Milky white cream | ≤20 | 85~90 | 68-73 | ≤1.0 | 5.0~7.0 | 14~14.5 |

| TX-15 | Milky white cream | ≤20 | 90~95 | 60~66 | ≤1.0 | 5.0~7.0 | 14.5~15 |

| TX-18 | Milky white cream | ≤20 | >95 | 53~58 | ≤1.0 | 5.0~7.0 | 15.5~16 |

| TX-21 | Milky white cream | ≤20 | >100 | 44~54 | ≤1.0 | 5.0~7.0 | ~16 |

| TX-30 | White solid | ≤20 | >100 | 34~39 | ≤1.0 | 5.0~7.0 | 17~17.5 |

| TX-40 | White solid | ≤20 | >100 | 26~31 | ≤1.0 | 5.0~7.0 | 17.5~18 |

| TX-50 | White solid | ≤20 | >100 | 21~25 | ≤1.0 | 5.0~7.0 | 18~18.5 |

3. Application Scope and Usage

TX emulsifiers are employed across many civilian industries: textile processing (scouring, mercerizing, dye leveling, anti-static finishing); agrochemical formulations (emulsifiable concentrates, micro-emulsions, suspension concentrates); household and institutional detergents (degreasers, hard-surface cleaners, car shampoos); industrial cleaning (metal degreasing, circuit-board flux removal); emulsion polymerization of acrylics, styrene-acrylics and vinyl acetate; paints & coatings (pigment wetting, latex stabilization); personal-care products (solubilizer for perfumes and essential oils); paper & leather auxiliaries; and oil-field chemicals (demulsifiers, corrosion inhibitors). Typical use levels are 0.1–2 % in cleaning baths, 2–6 % in emulsifiable concentrates, 1–3 % in emulsion polymerization, and 0.5–3 % in textile baths. Selection of EO chain length (TX-4 for W/O systems, TX-10/100 for O/W systems) allows fine-tuning of HLB and cloud point.

4. Package and Storage

The TX series products are packaged in 200 kg iron drums or 50 kg plastic barrels for liquid forms, while solid forms are sliced and packed in 20 kg woven bags. These products are non-flammable and can be stored and transported as general chemicals. They should be kept in a dry, well-ventilated area with a shelf life of two years.