【CAS】11138-66-2

Alias: Glucomannan Mayo;Galactomannane;Xanthangum,Fcc;x

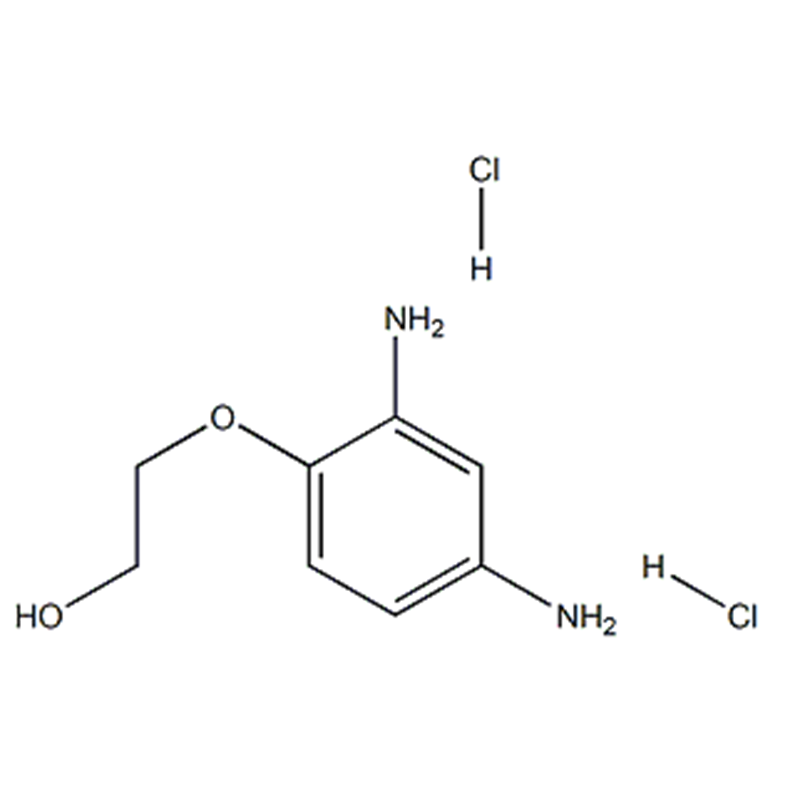

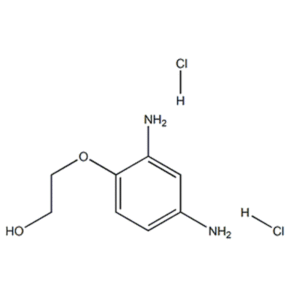

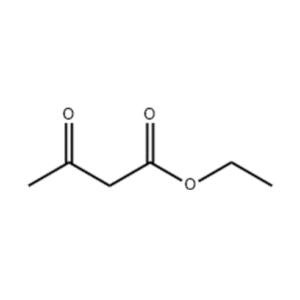

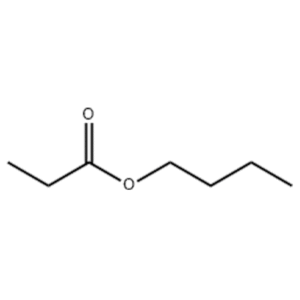

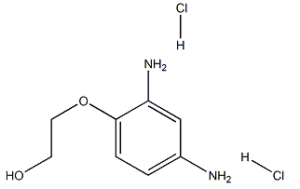

Chemical Formula: C8H14Cl2N2O2

Molecular weight: 241.11496

【Structural Formula】

1、Product Property

Food-grade xanthan gum is a product obtained after fermentation, extraction, drying and crushing of corn starch by Bacillus xanthomonas. It has excellent rheological properties and shear resistance, and is a hydrophilic biological polymer with thickening and stabilizing effects.Xanthan gum is a cream-colored, free-flowing powder produced through microbial fermentation. It dissolves readily in hot or cold water, forming highly viscous solutions even at low concentrations. The gum exhibits exceptional shear-thinning behavior and maintains viscosity stability across wide pH (2–12) and temperature ranges (up to 80°C).

2. Quality Standards

| Indicator | Specification Requirements | Test Method |

| Appearance | Light yellow to pale beige powder, low dust | DFFX001 |

| Particle Size | 100% passes 80 mesh (180μm), at least 92% passes 200 mesh (75μm) | DFFX004 |

| Viscosity | 1200-1700 cp (1% Xanthan Gum in 1% KCl Solution) | DFFX011 |

| Shear Performance | ≥6.5 | DFFX016 |

| V1/V2 | 1.02-1.45 | DFFX013 |

| pH | 6.0-8.0 (1% Solution) | DFFX006 |

| Dry Weight Loss | ≤15% | DFFX003 |

| Ash Content | ≤16% | DFFX027 |

| Lead | ≤2ppm | DFFX029 |

| Total Nitrogen | ≤1.5% | DFFX009 |

| Pyruvic Acid | ≥1.5% (Note: Original text had ‘Acetic Acid’, corrected to ‘Pyruvic Acid’) | DFFX008 |

| Total Bacteria Count | ≤2000 cfu/g | DFFX031 |

| Yeast and Molds | ≤100 cfu/g | DFFX032 |

| E. coli | ≤30 MPN/100g | DFFX033 |

| Salmonella | Negative | DFFX034 |

3. Application Scope and Usage

Xanthan gum serves as a thickener, stabilizer, and emulsifier in food products like sauces, dressings, dairy alternatives, and gluten-free baked goods. It prevents ice crystal formation in frozen foods and enhances mouthfeel in beverages. Industrial applications include oil drilling fluids, cosmetics (lotions), and pharmaceuticals (suspension agents). In agriculture, it’s used for pesticide encapsulation. Typical usage levels range from 0.1%–1.0%, adjusted based on desired texture and rheological properties.

4. Package and Storage

Packaged in 25 kg multi-layer kraft paper bags with polyethylene liners or fiber drums. Store in a cool (<25°C), dry environment away from direct sunlight. Ensure containers are tightly sealed to prevent moisture absorption and microbial contamination. The shelf life is 24 months.